Product Description

Highly heat-resistant, silicone-sheathed flexible cable

Applications

Silicone-insulated cables are used when exposure to high temperatures and temperature variations would cause conventional PVC-insulated cables to become brittle. Silicone-insulated cables are preferably used in the metallurgical industry, steel works, hot-rolling mills, coking plants, foundries, cement works, glass factories and ceramics plants as well as in the production of electric motors, in sauna construction, in ships and aeroplanes, in heat, refrigeration and air-conditioning technology, as well as in lighting gear etc.

The insulation consists of silicone rubber. It is halogen-free and resistant to vegetable and animal fat, many types of oil and diluted acids. No decomposition occurs when exposed to alcohol, plasticizers, alkaline solutions, saline solutions etc.

The insulation is fully tropicalized and resistant to oxygen and ozone. One of its exceptional features is its high flash point. Should the cable burn, an insulating silicon dioxide layer will remain on the conductor to render it short circuit proof.

Design

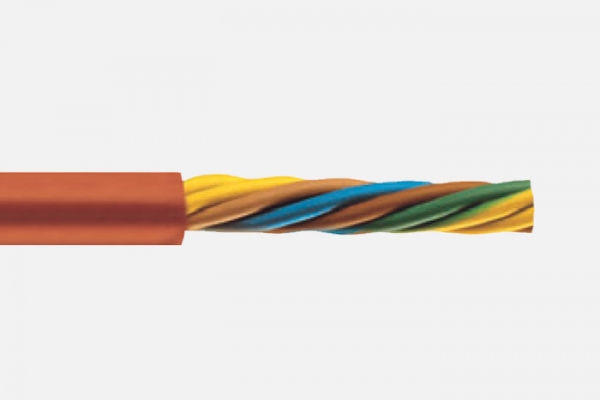

- Stranded tinned Cu conductor, fine wire

- Strand structure to VDE 0295 class 5 / IEC 60228 class 5

- Silicone-insulated cores

- Up to 5 cores: coloured cores to VDE 0293

- 6 cores and over: black cores with printed consecutive number coding

- Green-yellow protective conductor (3 cores and over) in the outer layer

- Cores twisted in layers, with optimal lay lengths

- Outer sheath: silicone

- Sheath colour: preferably reddish brown

Electrical and technical specifications

Rated voltage:

Uo/U 300/500 V

Test voltage: 2000 V

Insulation resistance: ≥ 200 MOhm x km

Bending radius: 15 x cable diameter

Temperature range: – 50° C to +180° C

temporarily up to +200° C

Flame retardant to IEC 60332-1

Halogen-free:

HCl emission to IEC 60754-1

Corrosiveness of combustion gas to

IEC 60754-2